Commercial-scale cellulosic ethanol plant opens

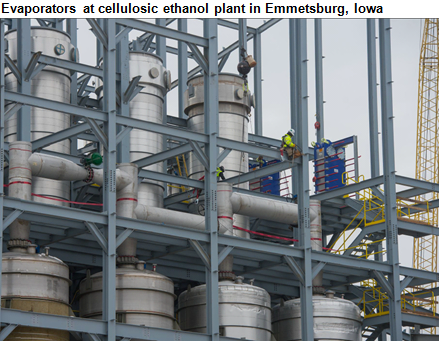

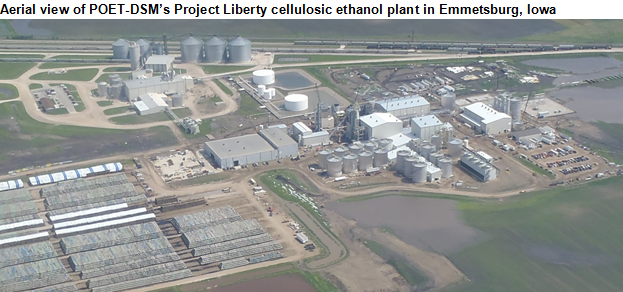

On September 3, a joint venture company called POET-DSM Advanced Biofuels held the grand opening of its Project Liberty cellulosic ethanol plant in Emmetsburg, Iowa. The plant is the first of three commercial-scale cellulosic ethanol facilities under development in the Midwest that convert corn stover (corn cobs, leaves, husk, and stalk) into ethanol.

The 50/50 joint venture Project Liberty is owned by POET of Sioux Falls, South Dakota, and Royal DSM, a Dutch company. At full capacity, the plant will process 770 tons/day of corn stover.

While nearly all ethanol produced in the United States comes from corn starch, ethanol can also be produced from cellulosic feedstock such as wood, grasses, straw, and agricultural waste. Despite legislated mandates as part of the federal renewable fuel standard (RFS), there has been very little production of cellulosic ethanol to date. For instance, the legislated RFS target volume for 2013 was 1 billion ethanol-equivalent gallons of cellulosic biofuel, which the Environmental Protection Agency (EPA) reduced to 6 million gallons in August 2013, based on its assessment of supply capacity. Ultimately, EPA retroactively reduced this requirement to 0.81 million gallons in May of this year, after production shortfalls.

The three facilities now under development or beginning operations in the Midwest (including Abengoa's 25-million gallon per year facility in Hugoton, Kansas; Dupont's 30-million gallon per year facility in Nevada, Iowa; and the POET-DSM plant) offer the best near-term prospects to prove technology for producing cellulosic ethanol at a meaningful scale. These plants use a more complex process than the recently announced effort to ferment the naturally accessible sugars present in corn kernel fiber into fuel, which only recently received EPA approval as a cellulosic biofuel meeting RFS criteria. The process used by POET-DSM, enzymatic hydrolysis, has been developed over many years and is one of the best understood ways to produce cellulosic ethanol. The first global commercial-scale application of this process occurred last fall when Beta Renewables started production at its Crescentino, Italy, facility. Beta's parent, BioChemtex, plans to start up a similarly designed plant with partner GranBio in Brazil later this year.

Principal contributor: Bill Brown